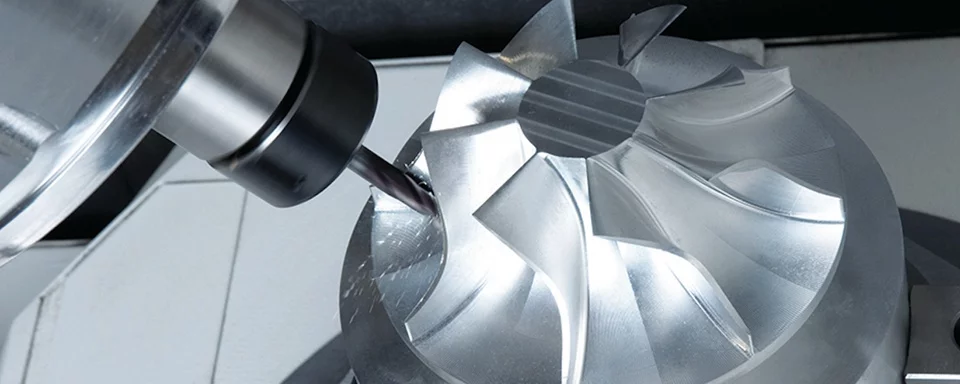

5-axis CNC milling, renowned for its precision in producing complex parts across industries, relies on various factors to determine service cycle times. Machine configuration, part complexity, material type, and operator expertise play pivotal roles.

Optimizing these variables in today’s fast-paced manufacturing environment is crucial to minimize delays and enhance productivity. This guide delves into the key factors influencing 5-axis CNC milling speed and provides strategies to accelerate machining processes for businesses.

Is 5 Axis CNC Mill Fast?

5-axis CNC mills are precise in producing complex parts and can work on five different sides of a part simultaneously, eliminating the need for multiple setups and tool changes. This capability significantly reduces production time compared to traditional 3-axis- or 4-axis CNC milling machines requiring more manual intervention.

Nevertheless, the 5-axis CNC mill speed depends on factors beyond the machine, including part complexity, material type, tool selection, and operator expertise. While 5-axis machining offers inherent advantages, it’s essential to recognize that cycle time can vary widely depending on these variables.

Optimizing cycle time is paramount in a precision CNC machining service and other manufacturing environments. It’s not just about whether a 5-axis CNC mill is fast; it’s about maximizing speed to achieve speedier service.

Key Factors that Affect 5 Axis CNC Mill Service Cycle Time

Several factors significantly impact the cycle time of a 5-axis CNC milling job, ultimately affecting the speed of service completion. Let’s delve into the most critical ones:

5-Axis CNC Mill Speed

The speed of a 5-axis CNC mill is heavily influenced by its configuration and capabilities. Simultaneous 5-axis machining, where all axes move simultaneously, generally operates faster than indexed 5-axis machining, where axes move sequentially. Additionally, machine specifications like spindle speed (measured in RPM), feed rate, and maximum travel limits affect the overall processing time. High-end machines with faster spindles and optimized software often yield shorter cycle times, although they can lead to high 5 axis CNC cost.

Part complexity

Part complexity also plays a significant role in determining cycle time. To maintain precision, parts with intricate features, tight tolerances, or complex curves may require slower machining speeds. These parts often involve more tool changes, different cutting paths, and frequent repositioning, which adds to the overall service time. On the other hand, simpler geometries are easier and faster to machine, making the 5-axis mill’s speed more noticeable.

Material’s Machinability

The machinability of the material being used also directly impacts how quickly the job can be completed. Soft materials like aluminum allow for higher-speed milling and faster cycle times. Harder or more exotic materials like titanium, Inconel, or hardened steel require slower feed rates, more durable tooling, and additional cooling measures to prevent tool wear and maintain quality, leading to extended service times. The material’s thermal properties, hardness, and composition must be carefully considered when calculating how quickly a part can be machined.

Tool selection and wear

Tool selection and wear also impact the speed of the 5-axis mill. The type of tool used and its wear rate can affect the machining speed and the overall processing time.

The type and condition of cutting tools, operator skill, and experience significantly impact cycle time in 5-axis machining. High-performance cutting tools, such as carbide or diamond-coated tools, designed to withstand high-speed operations and rigid materials, lead to faster cycle times. However, tool wear over time can slow down production. Regular tool maintenance and advanced coatings like titanium aluminum nitride (TiAlN) or diamond-like carbon (DLC) can extend tool life and reduce downtime.

Operator skill

Operator skill and experience are vital in optimizing cutting strategies, adjusting tool paths, and selecting the appropriate tools for the job. Experienced operators are adept at troubleshooting issues on the fly and minimizing delays. In contrast, less experienced operators may not fully utilize the machine’s capabilities, resulting in longer setup times and less efficient machining.

CAM programming and software optimization

CAM programming and software optimization are crucial in determining cycle time. High-quality CAM software with advanced features like toolpath optimization, automatic collision detection, and high-speed machining strategies can significantly reduce cycle times. Efficient programming results in smoother tool movements, fewer unnecessary tool changes, and optimized cutting paths that shorten the overall process.

Setup Time

Setup time is another aspect that affects cycle time. While 5-axis machining offers reduced setups, some setup time is still required before machining can commence. Proper alignment, workholding, and calibration are essential before the machine can start cutting. Reducing setup time through automated systems, quick-change fixtures, or modular workholding solutions can significantly enhance the overall speed of service.

Post-processing and inspection

Post-processing and inspection also contribute to cycle time. These processes involve additional time and resources, impacting the overall machining efficiency.

After the part is machined, it undergoes post-processing, which may include deburring, polishing, or applying surface treatments. These steps add to the overall service time. Additionally, parts must be inspected to ensure they meet specifications and tolerances. While necessary, these processes can prolong the cycle time, especially if any issues require rework.

How to Speed up 5 Axis CNC Mill Service

Several strategies can optimize the speed of 5-axis CNC service without compromising quality. By focusing on process improvements and adopting modern technologies, manufacturers can significantly reduce cycle time:

Optimize CAM Programming

One of the most effective ways to shorten cycle times is through optimized CAM programming. Utilizing advanced software with toolpath optimization, high-speed machining algorithms, and automatic collision avoidance can minimize unnecessary tool movements and enhance cutting efficiency. Implementing trochoidal milling, which employs a circular toolpath to maintain consistent engagement with the material, can also improve cycle times.

Utilize High-Performance Cutting Tools

Choosing the appropriate cutting tools is crucial for speeding up machining processes. High-performance tools for specific materials enable faster cutting speeds and reduced tool wear. Coated tools, such as those with titanium aluminum nitride (TiAlN) or diamond-like carbon (DLC) coatings, extend tool life and minimize the frequency of tool changes, further accelerating the process.

Leverage Simultaneous 5-Axis Machining.

Opting for simultaneous 5-axis machining instead of indexed machining allows continuous cutting on multiple axes. This eliminates the need for various setups and enables the machine to perform intricate cuts in a single operation, significantly reducing cycle time.

Implement Quick-Change Fixtures

Reducing setup time is one of the most effective ways to speed up the service cycle. Quick-change fixtures enable operators to swap out workpieces swiftly and precisely, minimizing downtime between jobs. Automated workholding systems further enhance this process by eliminating the need for manual adjustments.

Automating the Loading and Unloading of Workpieces

Automating the loading and unloading of workpieces can significantly reduce idle time. Robotic systems can handle repetitive tasks, allowing operators to focus on programming and quality control. This enables the CNC mill to operate continuously, further reducing cycle times.

Investing in predictive maintenance

Investing in predictive maintenance ensures that the 5-axis CNC mill operates at peak efficiency. Implementing predictive maintenance systems that monitor machine health in real-time can help identify potential issues before they cause downtime. This proactive approach keeps the machine running smoothly, minimizing unexpected delays and maximizing productivity.

High-efficiency milling strategies

Adopting high-efficiency milling strategies allows for faster material removal while minimizing heat generation and tool wear. Manufacturers can reduce cycle time by using shallow cuts at higher speeds while maintaining part quality. HEM strategies are particularly effective when machining challenging materials like titanium or Inconel.

Conclusion

Achieving a fast 5-axis CNC milling service is a complex challenge influenced by various factors, including machine configuration, part complexity, material type, and operator skill. However, manufacturers can significantly reduce cycle time and enhance productivity by optimizing CAM programming, utilizing advanced cutting tools, and implementing automation.

Incorporating high-efficiency milling strategies, such as utilizing quick-change fixtures and ensuring regular machine maintenance, is crucial for faster service. By prioritizing both speed and precision, manufacturers can optimize the benefits of 5-axis CNC machining to meet the demands of today’s fast-paced manufacturing environment.