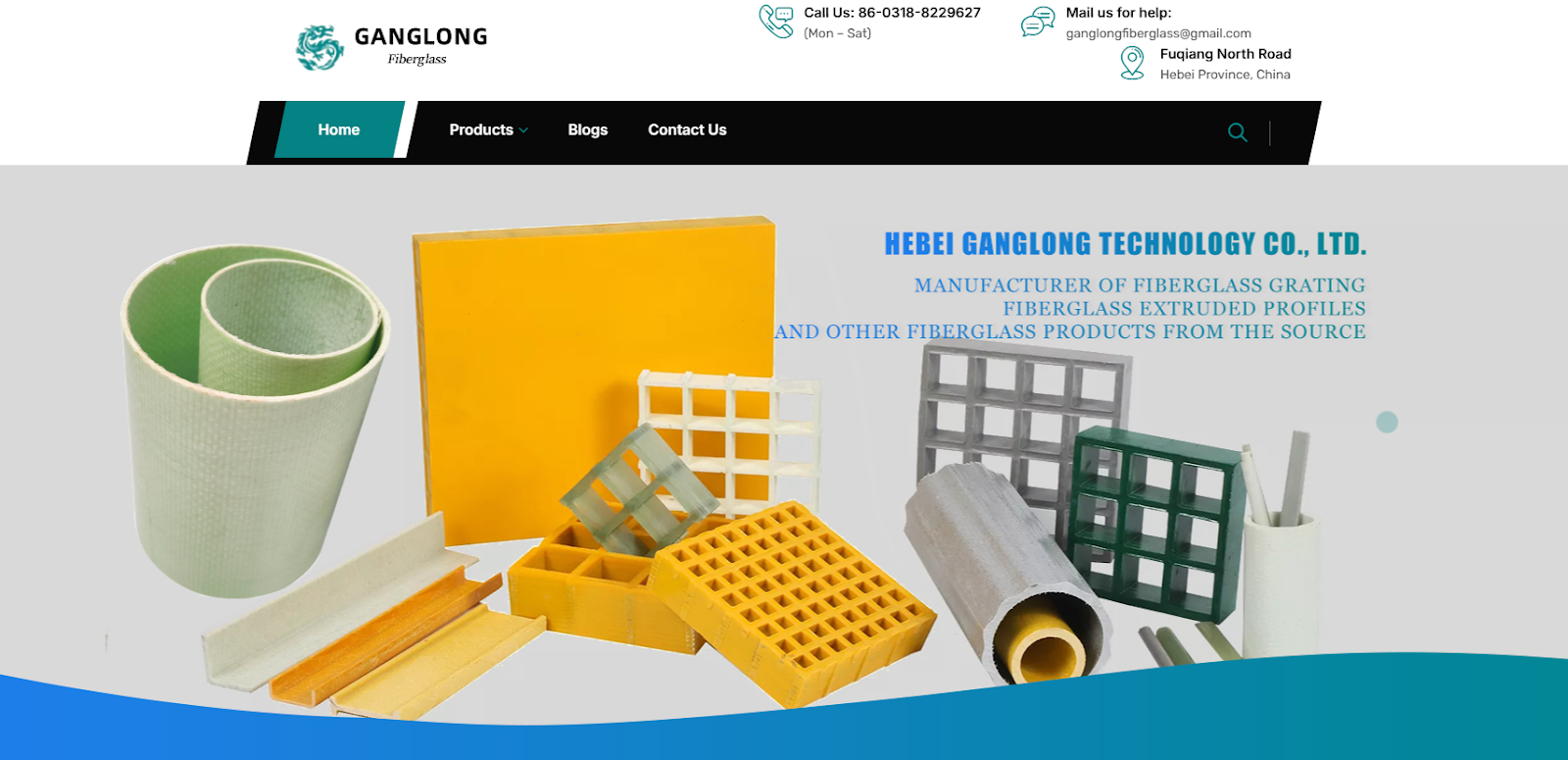

Why CSM is Preferred Over Metals, Wood, and Other Composites

Chopped Strand Mat (CSM) has become a preferred material in numerous industries due to its unique combination of properties, offering numerous advantages over traditional materials like metals, wood, and other composites. These benefits make CSM an ideal choice for applications that require strength, durability, and cost-efficiency, including in products like fiberglass sheets and cable ladder. Here’s a detailed look at why CSM is preferred over these conventional materials in such applications.

Weight Reduction

One of the most significant advantages of CSM is its lightweight nature compared to metals like steel and aluminum, and even wood. This is particularly crucial in industries like automotive, aerospace, and marine, where weight reduction is essential for improving fuel efficiency, reducing emissions, and enhancing overall performance.

- Metals: Metals, while strong, tend to be heavy, which can increase the weight of the final product, resulting in higher transportation and operational costs.

- Wood: Although wood is lighter than metals, it is less durable and requires regular maintenance to prevent damage from moisture, insects, and rot.

- CSM: Chopped Strand Mat, on the other hand, offers a much lighter alternative while maintaining excellent strength and durability, making it ideal for lightweight structural components without compromising performance.

Corrosion and Weather Resistance

CSM is inherently resistant to corrosion, unlike metals, which can rust and degrade over time when exposed to water, air, or chemicals. In applications like marine vessels, outdoor construction, and industrial settings, the resistance to corrosion is a crucial benefit.

- Metals: Steel and aluminum are prone to rusting, especially when exposed to moisture, saltwater, or harsh environmental conditions. This leads to the need for frequent maintenance or protective coatings.

- Wood: Wood can be vulnerable to decay, mold, and rot when exposed to moisture, which limits its durability in outdoor or harsh conditions.

- CSM: As a fiberglass-based material, CSM is impervious to rust, rot, and corrosion, making it a long-lasting option for applications that face constant exposure to water, UV rays, and extreme weather.

Durability and Strength-to-Weight Ratio

CSM’s impressive strength-to-weight ratio makes it a superior material in applications requiring both strength and minimal weight. It can provide exceptional durability while being much lighter than metals or wood, which often compromise one for the other.

- Metals: While metals like steel are strong, they can be heavy and prone to bending or denting under stress.

- Wood: Wood, while naturally strong in some forms, lacks the consistency, resilience, and strength of CSM, especially in heavy-duty applications.

- CSM: CSM, made from glass fibers, provides an excellent combination of strength and flexibility, making it suitable for everything from automotive parts to infrastructure components.

Ease of Manufacturing and Molding

CSM’s ability to be easily molded into complex shapes is another significant advantage over traditional materials. It can be used in large-scale production processes, where precise shapes are required with less effort than metals or wood.

- Metals: Metals require more intensive manufacturing processes like welding, stamping, or machining, which can be time-consuming and costly.

- Wood: Wood can be shaped and molded, but it often requires additional treatments and is more vulnerable to inconsistencies in grain and structure.

- CSM: CSM can be molded and formed into complex shapes using relatively simple processes like hand lay-up, injection molding, or vacuum infusion. This reduces manufacturing costs and improves efficiency in production.

Environmental Impact and Sustainability

With growing emphasis on sustainability, CSM presents an environmentally friendly alternative to traditional materials like metals and wood. The sustainability of CSM is largely due to its recyclability and the fact that it’s made from abundant raw materials.

- Metals: While metals like aluminum are recyclable, the energy-intensive process required to recycle metals can negate some of the environmental benefits.

- Wood: While renewable, wood is often subject to deforestation concerns and requires careful sourcing and management to ensure sustainability.

- CSM: Fiberglass, the primary material used in CSM, is made from silica, a natural and abundant resource. Moreover, advances in recycling technologies are making it possible to recycle fiberglass composites, including CSM, reducing their environmental footprint.

Cost-Effectiveness

CSM offers a cost-effective alternative to metals and wood, especially in large-scale applications. Its relatively low production cost, coupled with its ease of handling and molding, makes it a financially attractive material.

- Metals: Metals like steel and aluminum can be expensive to procure and manufacture, especially when considering the cost of maintenance and protective coatings over time.

- Wood: While wood may seem cost-effective initially, the need for treatment, maintenance, and vulnerability to damage over time can increase the overall cost.

- CSM: CSM is a more affordable option, particularly when considering the reduced costs associated with its durability and minimal maintenance needs.

Fire Resistance

CSM offers excellent fire resistance compared to wood and some metals. Its inorganic composition makes it highly resistant to combustion, offering safety benefits in certain applications like construction and automotive.

- Metals: While metals are fire-resistant to some degree, they can conduct heat, making them less ideal in fire-resistant applications that require thermal insulation.

- Wood: Wood is highly combustible and, without treatments, can easily catch fire and contribute to spreading flames.

- CSM: CSM is non-combustible and offers high fire resistance, making it suitable for fire-sensitive environments, including fiberglass sheets used in building firewalls or cable ladder in high-temperature areas.

Thermal Insulation Properties

CSM is known for its ability to insulate against temperature extremes, making it an ideal choice for applications where thermal insulation is important.

- Metals: Metals can conduct heat and cold, which may lead to energy inefficiency or thermal discomfort in certain applications.

- Wood: While wood has some insulating properties, it is often insufficient in high-performance applications requiring precise thermal control.

- CSM: The structure of fiberglass in CSM makes it an effective insulator, helping to maintain temperature control in both high and low temperatures.